|

New Energy Research Laboratory Device

and Process Testing Update

Published in IE Issue #36, March/April

2001

by Ken Rauen and Eugene Mallove

First Gate Energies' Sonofusion Reactor:

Initial Validation at 50% Excess Heat

Success is especially sweet when one has been

trying for a long time, without much success, to identify and develop

a robust demonstration device for cold fusion phenomena- excess

heat and nuclear effects. Such a device now appears to be close

at hand in the sonofusion reactor of Roger Stringham and his colleagues

at First Gate Energies. In mid-February Ken Rauen, as lead investigator,

succeeded in reproducing the approximate excess heat results that

Stringham had obtained in the same reactor when it was in his California

lab (see IE, No. 35, p. 21, p. 70). Figure 1 is a sample

of one stretch of excess power, varying with the unknown conditions

on the surface of a copper foil target in heavy water. This was

under pulsed acoustic dual-transducer activation with approximately

40 kHz wave packets.

Figure 1. Sample of one stretch of excess power. The exess heat

line is marked with an arrow and appears darker than the adjacent

lines. The "Ref" line on the Y axis is zero watta

excess heat. Vertical scale is 2 watts/division. The cyclic

fluctuations are due to furnace cycling to keep the lab warm,

as it is winter in New Hampshire. |

With a margin of error in the preliminary

result that we believe to about ±0.5 watt (certainly no more than ±1 watt), we have high confidence that excess heat has been

faithfully reproduced. We have confidence in the joule heater

calorimetric calibration of both the input acoustic signal oscillator

electronics and the reactor itself, which has a built-in joule heater

calibration. Given the experience of Stringham in producing similar

results on demand over many years, we believe this is an excellent

candidate to be a robust demonstration of cold fusion phenomena.

Many new experiments need to be performed, including attempts

to reduce or zero the excess heat by employing ordinary water and

some other metals, reducing argon pressure, lowering input power

below a critical value, etc. (The excess heat is said to be so frequently

part of any such sonofusion reactor work, that in this instance

the best "null" is found by cross checks on the calorimetry; we

have already carried these out.)

Though much work remains to be done in getting onto market with

this scientific demonstration device, First Gate Energies has agreed

to allow NERL to be the exclusive developer, marketer, and distributor

of scientific demonstration educational kits based on Stringham's "M3S" sonofusion reactor. (Those who would consider obtaining such

a research kit are asked to contact NERL as soon as possible, to

establish priority and help us anticipate production runs. Note

well: We will not distribute such kits until we are certain that

we can guarantee excess heat results on demand.)

|

|

Figure 2a. Set-up schematic of sonofusion

reactor.

|

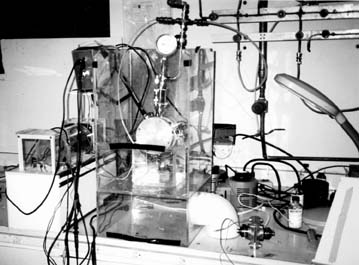

The road to successful confirmation was

not easy. After Eugene Mallove's visit last fall to the First Gate

Energies laboratory in California, Roger Stringham sent to NERL

in Bow, New Hampshire the M3S sonofusion reactor, its Plexiglas

test stand, and its transducer electronics calorimeter. The set-up

can be seen schematically in Figures 2a and 2b. A picture of the full system at NERL with

our Toshiba laptop computer data acquisition system appears in Figure

3 while it was producing excess heat on February 17. The reactor

seals had developed leaks from prolonged use by Stringham and perhaps

from the transport. During various stages of replacing seals, leaks

and input power losses occurred, in one case due to ultrasonic power

absorption in soft-rubber replacement seals; we reverted to Teflon

seals.

Our data acquisition system software is BenchlinkTM

(by Agilent/HP), which allows up to twenty-two channels of thermocouple

and input power measurements via an Agilent/HP 34970a Data Acquisition

Switch Unit, which periodically scans all input channels.

|

| Figure

2b. Set-up schematic of sonofusion reactor. |

The very first run of the sonofusion reactor,

with the new teflon gaskets, produced excess heat with good confidence.

The excess power was initially 2.5W, with about 5W of ultrasonic

energy into the reactor (5 watts in, 7.5 watts out). From the calibration runs and from two control tests during

the run, we are confident that the error margin of this experiment

is about 6 0.5W.

As a confidence check, Ken Rauen turned off the oscillator electronics

and moved the oscillator cooling loop thermocouple from the calorimeter

box to the piece of steel which houses the ambient temperature recording

thermocouple; there was a mere 0.15°C difference. The associated

excess heat error is no more than +/- 0.2W, as expected in this

zeroing of input. Later, after a day or more of operation, the excess

heat increased to a higher level-up to 8 watts, but it also dipped

periodically, though never approaching zero. We know that for an

unknown reason reactor calibration changed, so our confidence in

the 100% figure is not good.

The thermocouple was then replaced into the oscillator electronics

calorimeter with oscillator power off. The oscillator calorimeter

without its circulation fan cools very slowly. It was allowed to run overnight to see

if the temperature difference would drop to zero. It went to 0.2°C, which results in about

0.5W of excess heat calculated. We discount this zero check, as the offset is not an offset

in the heat calculation; the equation is nonlinear. The placement of the two thermocouples in the same environment

is a better check of the system in our opinion. The next step was to increase the reactor heater power to

reach temperatures seen by Roger Stringham as necessary for good

performance. The first excess heat run was about 95

to 100°C, possibly too cold for optimal cold fusion. Better results

were found at 108°C.

We intend to redesign the system for the educational kit such that

an accurately known bias joule heater power of over 50 watts is

not required to keep the reactor at operating temperature. This

can be done by appropriate insulation to make the reactor self-heat.

We also intend to perform gas sampling in order to detect the helium

that Stringham has previously reported emanating from this reactor.

Scientific demonstration kits will have gas sampling facility provided

with them so that gas can be sent for testing for helium at centers

with quadrupole mass spectrometers that are suitable for such refined

testing.

|

|

|

Figure 3. Stringham set-up.

|

Figure 4. Thin copper target showing hole.

|

A curious phenomenon occurred in initial

testing, before we detected excess heat. The thin copper target

that Stringham had provided to us developed a small hole in it! Such holes had previously been reported in sonofusion targets,

but usually with attendant visual evidence of melting. This target

(5 mil thickness) had rough edges under microscopic examination

that were unlike those in simple tearing of copper sheet of the

same thickness (see Figure 4).

Later, we observed the central perforation of the copper target

with which excess heat was detected. This time there was evidence

of surface thermal and mechanical damage. Fertile ground for investigations

of many kinds.

|

|